Transform Your Valve Testing Process with Our Innovative Safety Valve Leak Test System

Welcome to the future of safety valve leak detection! Our cutting-edge Vision-based Safety Valve Leak Detection System is revolutionizing the manufacturing industry by replacing outdated systems that have been in place for over 35 years. With our state-of-the-art technology, we have streamlined the process, reducing the skill set required and minimizing human errors.

Our Vision-based Safety Valve Leak Detection System utilizes advanced computer vision algorithms and high-resolution cameras to detect and analyze leaks in safety valves with unparalleled accuracy and efficiency. This innovative system not only improves the overall manufacturing process but also enhances the quality and reliability of safety valves, ensuring optimal performance and peace of mind for your customers.

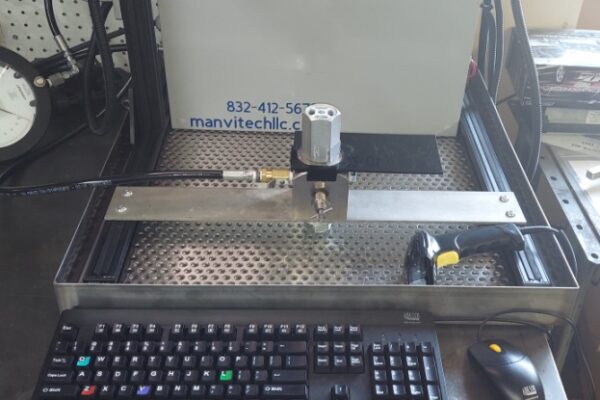

Valve Leak Test System Setup

Before - Old System

Front View

Valve Under Testing

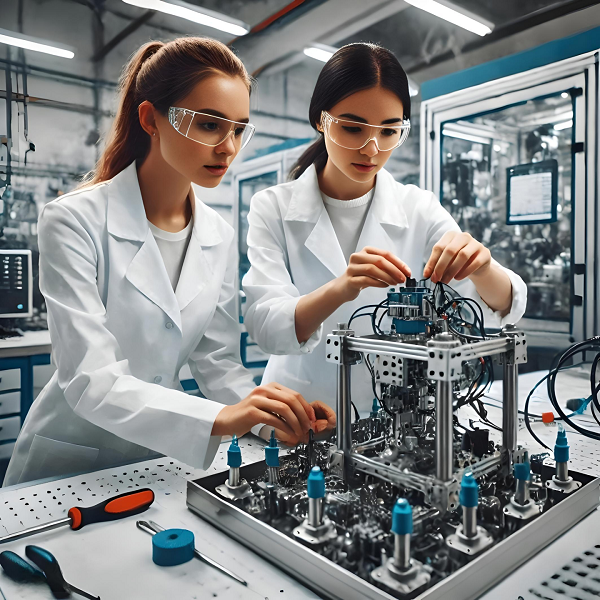

After - Overall System

Key Features and Benefits

Unmatched Precision: Our Vision-based System employs advanced image processing techniques to detect even the tiniest leaks in safety valves. It can identify leaks that might have been missed by older systems, guaranteeing the highest level of precision in leak detection.

Enhanced Efficiency: By automating the leak detection process, our system significantly reduces the time and effort required for manual inspection. It eliminates the need for intricate and time-consuming procedures, enabling faster throughput and increased productivity in your manufacturing operations.

Skill Set Reduction: Our Vision-based System simplifies the leak detection process, eliminating the need for extensive training and specialized skills. The user-friendly interface and intuitive controls make it accessible to operators of varying experience levels, reducing the dependency on highly skilled personnel.

Upgrade to our Vision-based Safety Valve Leak Detection System and experience a new level of efficiency, accuracy, and reliability in safety valve manufacturing. Let us help you improve product quality, streamline operations, and enhance customer satisfaction. Contact us today to schedule a demonstration and unlock the potential of advanced leak detection technology.

Minimized Human Errors: Human errors are inherent in manual inspection processes. Our Vision-based System mitigates this risk by providing consistent and reliable results, independent of operator subjectivity or fatigue. This leads to higher accuracy in leak detection and reduces the likelihood of costly errors and product recalls.

Real-time Monitoring and Analysis: Our system continuously monitors the safety valve manufacturing process, providing real-time feedback on leak detection. It offers instant notifications and alerts for any detected anomalies, empowering operators to take immediate corrective actions, ensuring the production of flawless safety valves.

Comprehensive Reporting and Data Analytics: Our Vision-based System generates detailed reports and analytics, allowing you to gain valuable insights into your manufacturing process. You can track historical data, identify trends, and make data-driven decisions to optimize your operations, increase efficiency, and drive continuous improvement.